Detailed Product Description

I. Introduction of URNDT Wire Rope Online Real-time Automatic Inspection System

As a high risk component of hoisting, lifting and conveying equipments, wire rope is regarded as the “lifeline” in many industries. However, the safety of in-service wire ropes has always been the “blind spot” or “source of danger” in equipment management, because of the lack of reliable testing instrumentation. How to detect the deterioration of in-service wire ropes and ensure their safety is an urgent demand for wire rope users.

URNDT Wire Rope Online Real-time Automatic Inspection System has achieved for the first time in the world automatic inspection of in-service wire ropes. As a more convenient and reliable inspection instrument, it helps users monitor the ropes safety status in real time, prevent accidents caused by rope failures, scientifically reduce the cost of wire rope use, and effectively increase production efficiency.

URNDT Wire Rope On-line Automatic Inspection System has fundamentally changed the situation of wire rope inspection and management. Compared to existing inspection instruments, the detectability of the URNDT on-line system is much higher for Localized Flaws (LF) such as broken wires, abrasion, corrosion and fatigue, and its precision is much accurate for the Loss of Metallic Cross-Sectional Area (LMA) and rope diameter shrinkage. It can not only detect various flaws, but also classify them into four flaw categories as broken wire, corrosion, abrasion and fatigue. It could calculate the value of broken wires per unit of wire length, according to industry standards of different countries. In addition, it can correctly evaluate the test wire rope’s safety status, residual bearing capacity and service life. Thereby, it has solved the three challenges of wire rope application – “hidden dangers, waste and low efficiency” and helped wire rope users achieve “safety, economy and efficiency.” It has been recognized as the most advanced wire rope NDT inspection system in the world.

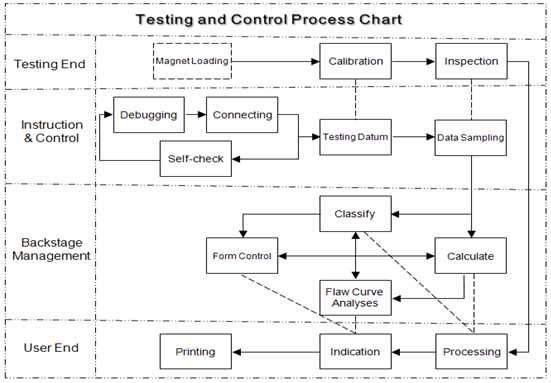

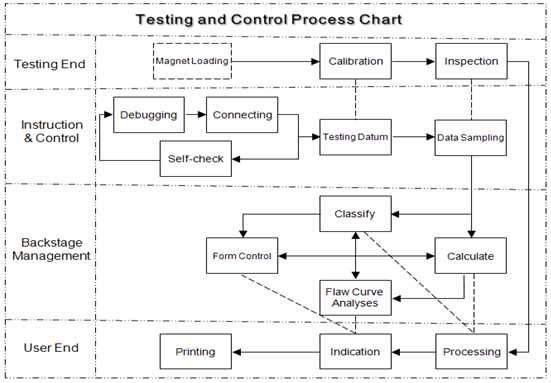

II. URNDT System Workflow Chart

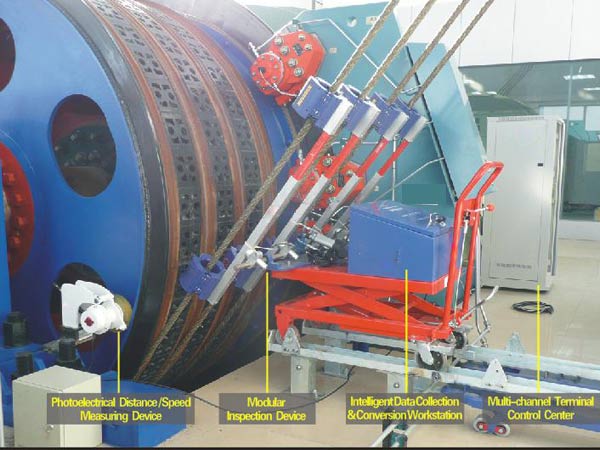

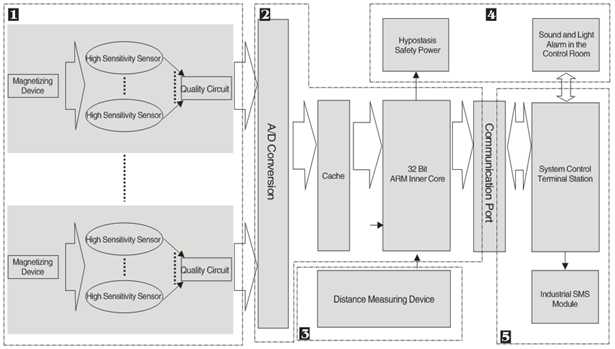

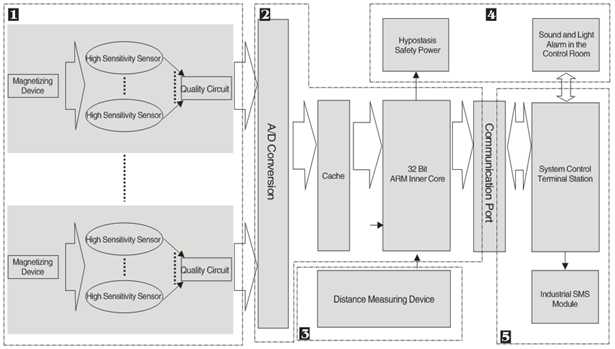

URNDT Modular inspection Device: Installed at the chosen location, it will automatically inspect the wire rope during normal production operation. The basic steps include the following:

1. Magnetize the wire rope with URNDT Weak Magnetic Loader to prepare it for inspection.

2. Retrieve and send holographic signals from the target wire rope by URNDT high-performance sensor unit.

URNDT Intelligent Data Collection & Conversion Workstation (DCCW):After receiving the original testing signals, the multifunction DCCW converts the analog signals to digital signals, processes and stores the original testing data, and communicates the processed digital data in real time to the Terminal Control Center for further analysis.

Distance Measuring Device links with coupling machinery of target wire rope, generates pulse signals for position information according to the running position of wire rope and send the position signals and defect signals of wire rope to main control station synchronously

URNDT Self-controlled Sound/Light Alarm Device: It provides early-warning signals according to the data processing result by the DCCW. The warning signals represent different safety status of the wire rope and are based upon the damage degree of the tested wire rope and relevant industry standards.

Green Light: the wire rope is in safe condition, and all the detected flaws are lower than 60% of the security warning level.

Yellow Light: more regular maintenance is needed as flaws, with values bigger than 60% and smaller than 90% of the security warning level, are detected.

Red Light: the wire rope is in serious danger, and severe flaws are detected, with values above 90% of the security warning level.

URNDT Multi-channel Terminal Control Center: It executes comprehensive analysis of the received testing data and generates daily test report about the target wire rope’s safety status and the trend of damage development. It allows the user to retrieve testing information of the target wire rope at present and a historical time about its damage status and degradation trend, with detected flaws specified by their values, positions, types and curves. All the information could be displayed and printed out. The Test Report presents the testing results in both flaw curves and numerical data table, which help the user know the target wire rope’s safety status just at a glance.

III. URNDT System Configuration

① URNDT Modular inspection device

-On-line installation and automatic operation

-Wide-space and non-contact inspection to ensure safety operation of the inspection device

-Real-time non-destructive testing for flaws when wire ropes in normal operation

-Weak magnetism sensors with high sensitivity, high stability and high responsiveness

-Suitable for all-weather indoor and outdoor working environments, with rain-proof, shock-proof, and oil-proof design.

-Routine maintenance free.

② URNDT intelligent data collection & conversion workstation

-Intelligent multi-channel two-way automatic information communication mode

- Modular multi-function unit combination, easy for updating.

-Shield-type information receiving & conversion and anti-interference design.

-Embedded real-time alarming program, with “yellow light” for early warning flaws and “red light” for over-limit warning flaws.

③URNDT-GMS Distance Measuring Device

-Adopt high-precision explosion-proof photoelectrical encoder and light aluminum frame

-Anti-loosening mechanical structure, self-clamp-floating cantilever support, and friction wheel with multi-channel anti-slip rings ensure reliably distance measuring

-Integrated anti-shake, pulse shaping and other industrial designs with features of stable signal and high accuracy distance measuring

④URNDT self-controlled sound and light alarm system

-Real-time and graded alarming responses, with “yellow light” for early flaw warning and “red light” for over-limit flaw warning.

-With over-limit flaws, the “red light” will be on and pre-programmed safety measures will be acted simultaneously.

-High-power on-site sound and light displaying device

URNDT Safety Status Reporting Function

Based on the real-time monitoring results and historical statistics, the alarm information will be showed and locked in terminal interface. The corresponding alarm information can be remotely sent to manager’s mobile phone by SMS according to the system pre-lock

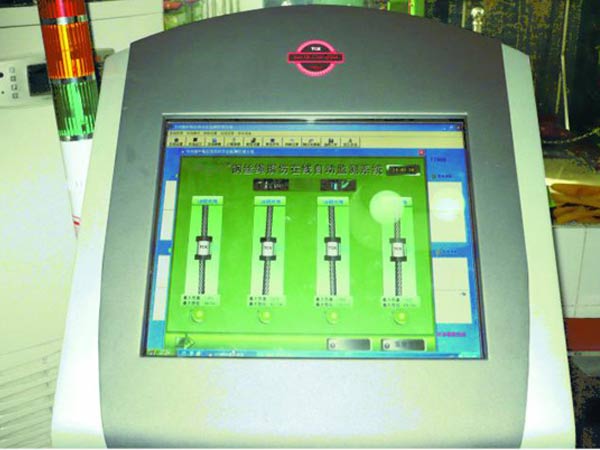

⑤URNDT Multi-channel Terminal Control Center

-Multi-channel step-by-step calling, synchronous and high speed data receiving & sending operation mode, optional configuration for wire/wireless communication.

-URNDT designated command and control system software, manual/auto switch operation mode.

-Windows operation platform with URNDT professional interfaces, Chinese/English language dialog windows operation mode.

-Compatible with the LAN or public network for information sharing.

-Real-time testing data collecting, analyzing and processing, with file-type data management system.

- Support testing data retrieving and test report printing whenever needed.

-Provide evaluation of wire rope residual bearing capacity, safety coefficient, and service life.

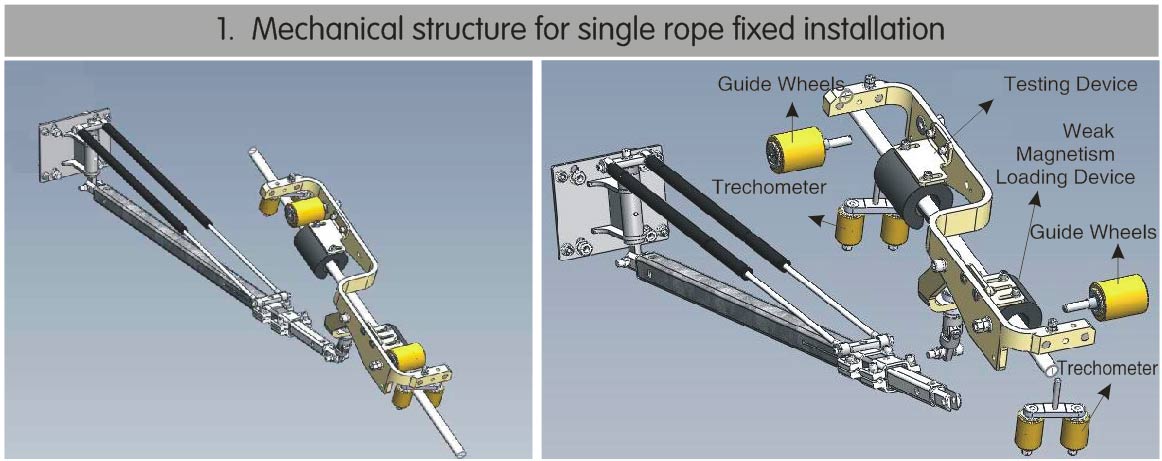

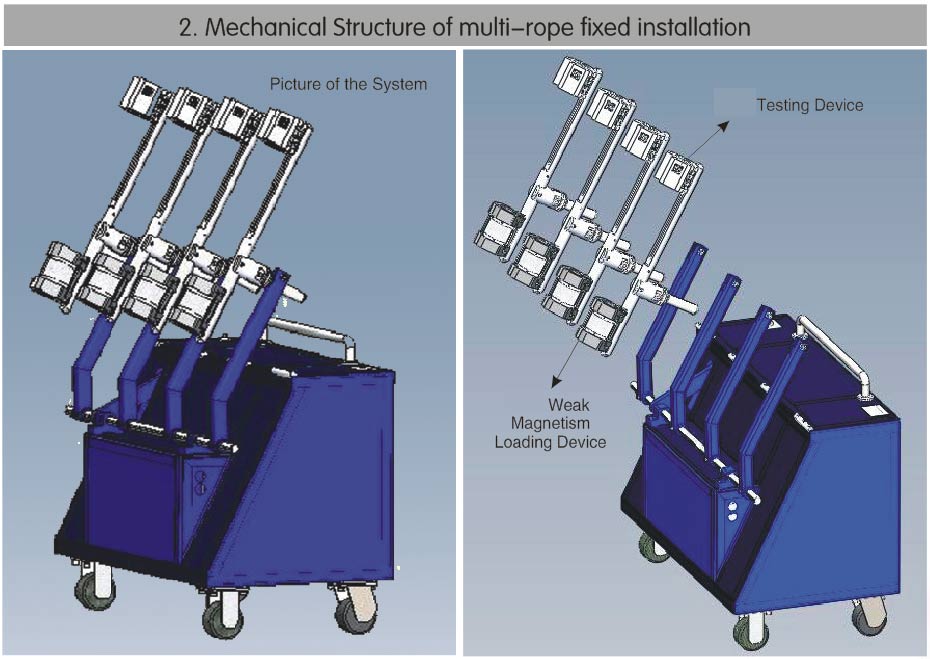

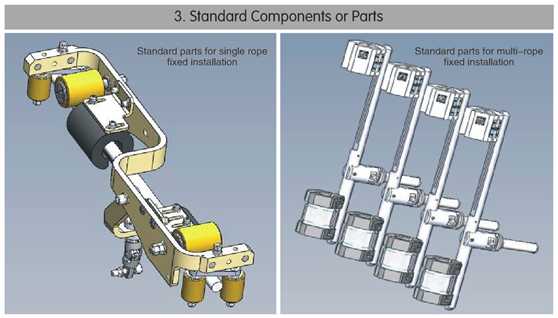

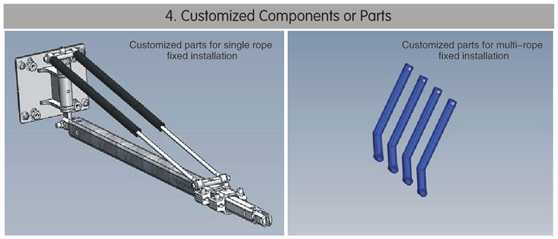

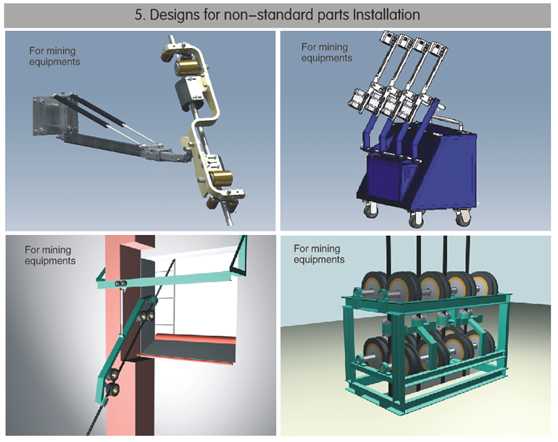

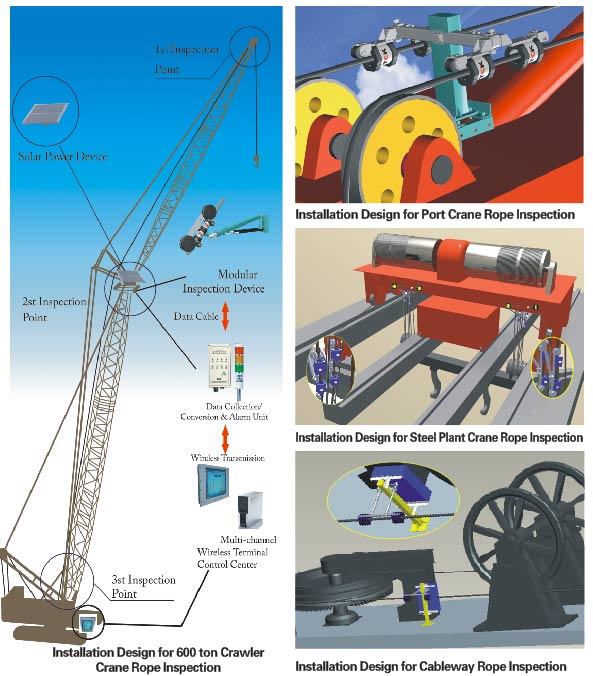

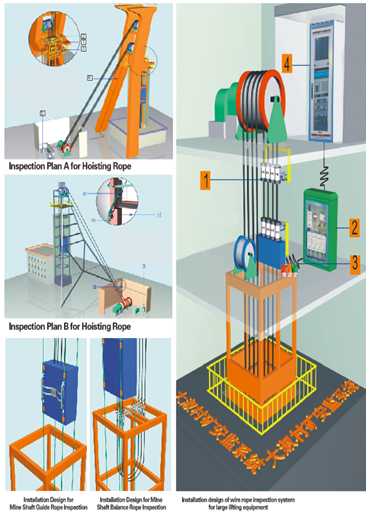

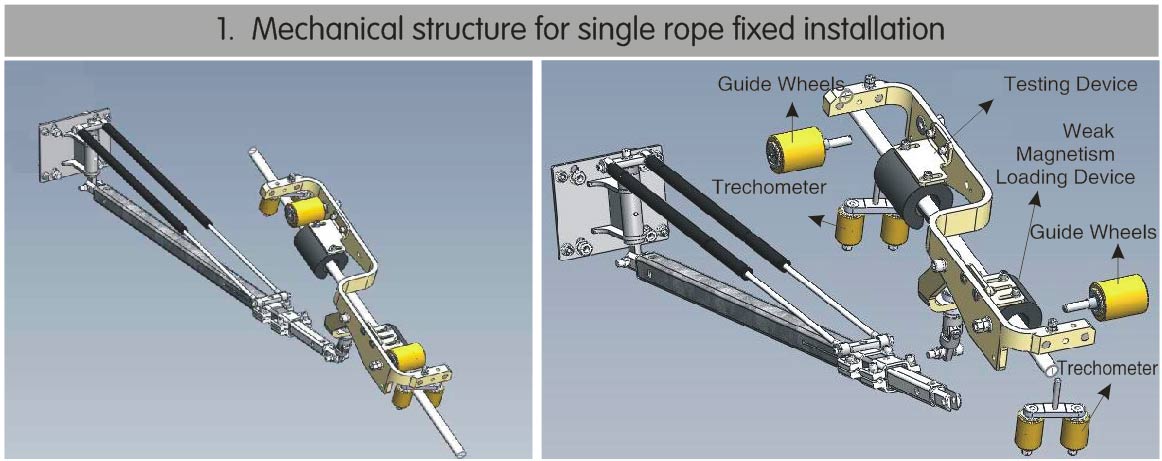

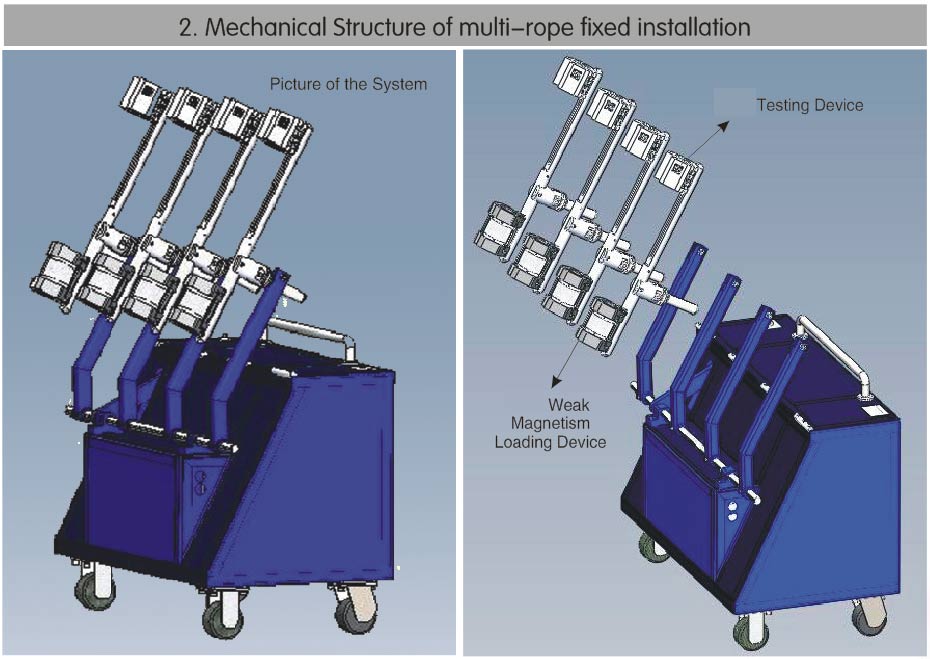

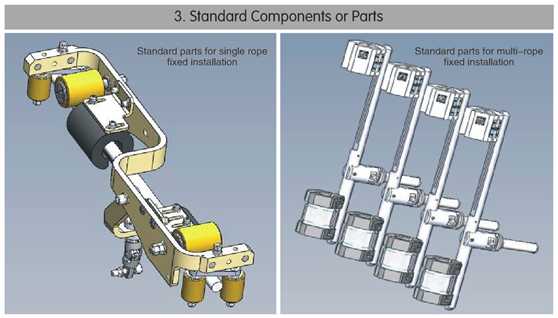

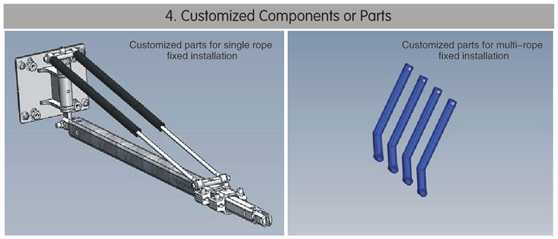

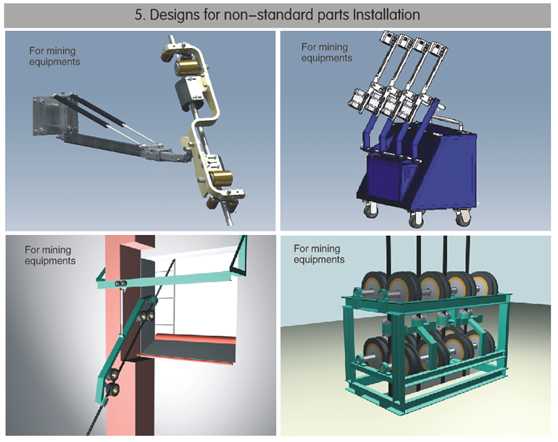

IV. Mechanical and Installation Structures

(Customization is available according to specific working conditions)

Customer-centered product design: the guide wheels and trechometer are easy wear parts, which are designed to be easily replaced by the customers.

The standard components or parts will be supplied by URNDT. As for the non-standard or customized components, they could be provided by URNDT or by the customers themselves. If the customers choose URNDT to supply the non-standard parts, extra charge will be applied.

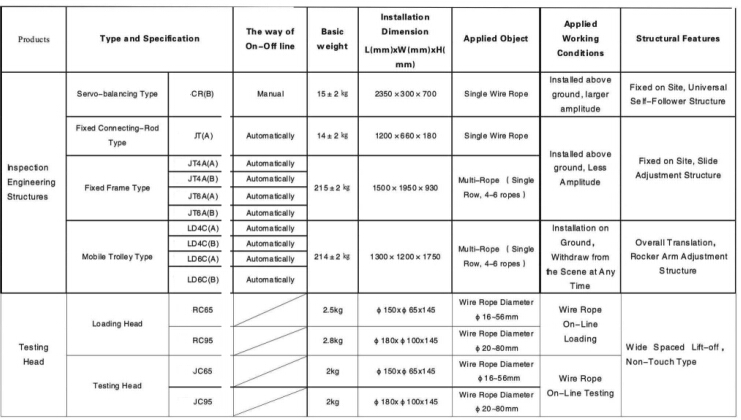

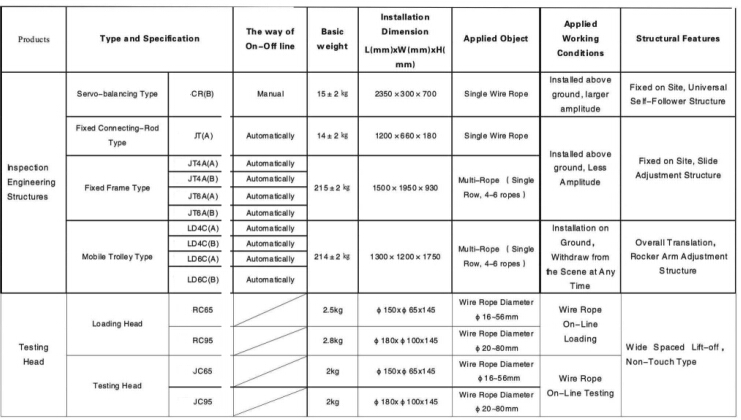

V. Table of Specifications and Parameter

V. Table of Specifications and Parameter

VI. Technical Parameters

System Default Parameters:

1. Sensitivity: >1.5V/mT

2. Sampling frequency response: ≤8kHz

3. System working voltage:AC220V±10%(explosion-proof)、AC127V±10%(explosion-proof)

4. System rated power capability: <200W

System Performance Parameters

5. Positioning inspection resolution :1mm;

6. Uncertainty rate of quantitative inspection (P):<1%

7. Maximum value of vibration range of wire rope:L=(Inner diameter of testing head-diameter of wire rope)×0.8/2

8. Accuracy rate:

100% For limiting value defects: Detectability = 100%

>99% For dangerous value defects: Detectability = 99%

>95% For normal value defects: Detectability > 95%

>70% For minor value defects: Detectability > 70%

Minor defects: actual defect value is less than 30% of the discard value;

Normal defects: actual defect value is more than 30%, but less than 60% of the discard value; which will not affect the safety of wire rope

Dangerous defects: actual defect value is more than 60%, but less than 90% of the discard value; which will affect the safety of wire rope gradually

Limiting defects: actual defect value is more than 90% of the discard value; which will affect the safety of wire rope directly

System Applicability Parameters:

9. Inspection range of rope Diameter,

Inspection Range for Model 65:φ16 ~56mm;

Inspection Range for Model 95:φ20 ~80mm

10. Testing Speed: V = 0-13m/s

11. Distance for signal transferring:

length of cable connected:≤80m(extendingto 1KM with relay station 1km)

length of optical fiber cable connected:≤10 km

12. Dimension between ropes: <φ175mm x1200mm

13. Working environmental temperature:-20℃—+40℃

14. Degree for dust-proof and water-proof:IP54

VII. Product Features

1. Modular components such as URNDT weak magnetism sensors, high-capacity data collecting system and other accessories are already produced in mass quantity.

2. Proven leading technology and high inspection accuracy

It makes possible to integrate wire rope online inspection and routine equipment management by combining quantitative inspection NDT technology with remote network communication technology. The inspection result is accurate and of high reference value. This makes wire rope daily inspection an easy and reliable task.

3. Good compatibility and easy to manage.

Supported by advanced quantitative inspection NDT technology and proven expert evaluation system, it does not interfere with the normal operation of the other equipments. The URNDT professional software operates independently, and is compatible with other operating systems.

4. High System operation stability

Professionally designed, it is suitable to operate in different working environments such as open country, high altitude and underground. It is not constrained by regions and severe working conditions. Also, it is not affected by mechanical vibration and electromagnetic interference.

5. Easy to operate and maintain

Specialized engineering installation, long-term maintenance-free for outdoor equipment, safe and reliable operation of software, with maintenance and upgrading services provided continuously.

6. Low operation cost and remarkable economic returns.

For the large number of in-service wire ropes, it helps avoid accidents caused by rope breakage, reduce rope use cost and increase effective working time of production equipments, resulting in high return on investment.

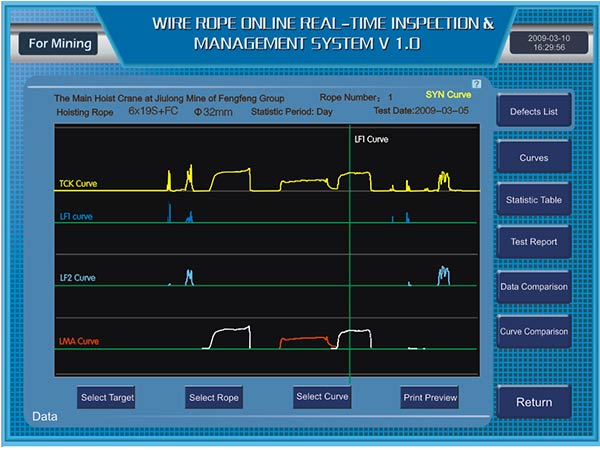

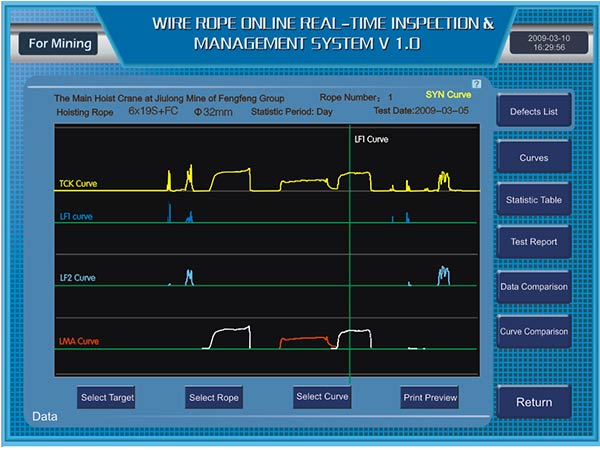

VIII. URNDT Software

URNDT wire rope online Real-time automatic inspection system, adopted professional computer-controlled applications, achieved unattended, automatic inspection, automatic data integration, automatic generating inspection reports and other systematic functions. According to industry-based monitoring and management approach, the system possesses the powerful functions, such as data form / defect curves / statistic charts multiple presetting, underground data calculating, automatic building file, system self-diagnosis, and predictive failure disposal, etc

URNDT Curve Represent the combined value of Loss of Effective Bearing Metallic Area (LMA)and Localized Flaws(LF).

LF1 Curve Represent wires.

LF2 Curve Represent the value of fatigue.

LMA Curve Represent of abrasion and corrosion.

This software is protected by the National Software copyright (Registered number:2007SR05880)

URNDT Wire Rope Online Real-time Automatic Inspection System is able to provide users with the most visual damage of wire rope inspection report from different angles:

1.Testing and Control Process Chart

2. Analysis Interface and Test Reports

(1)Defect Curve

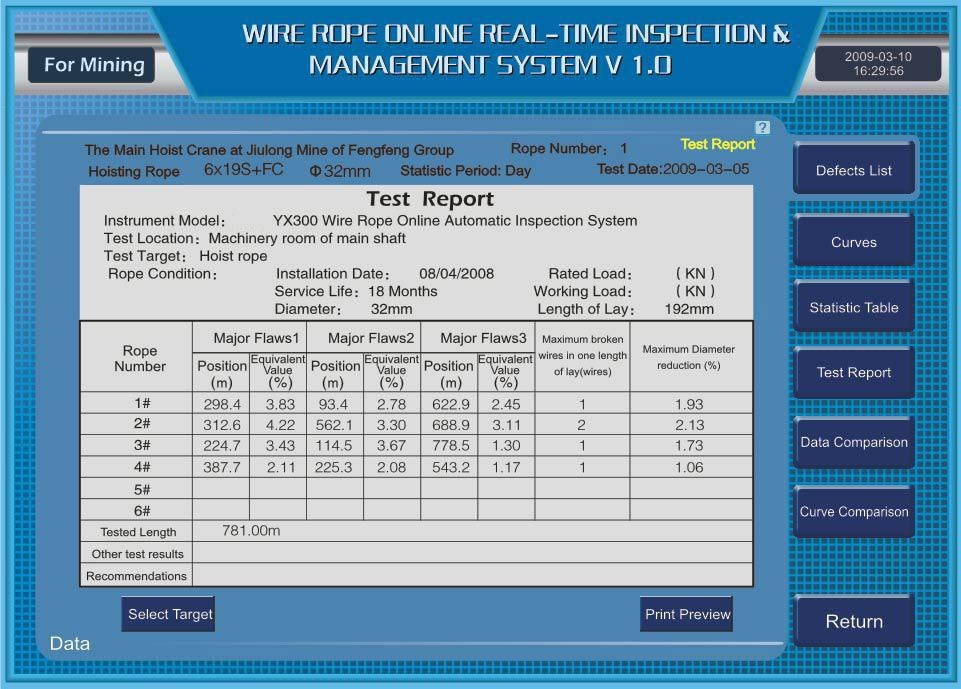

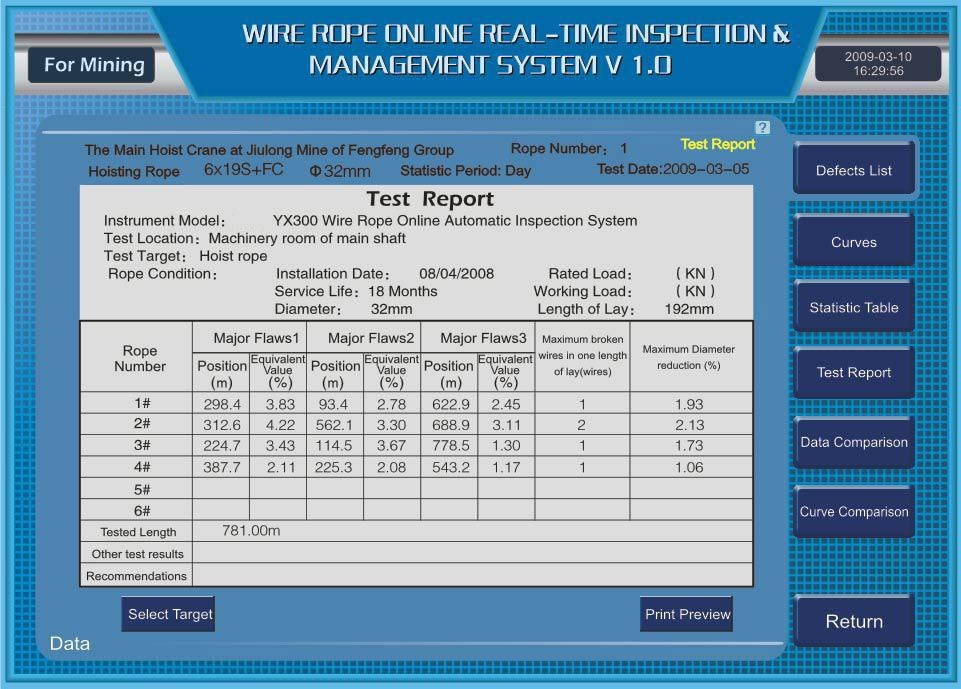

(2)Test Report

(2)Test Report

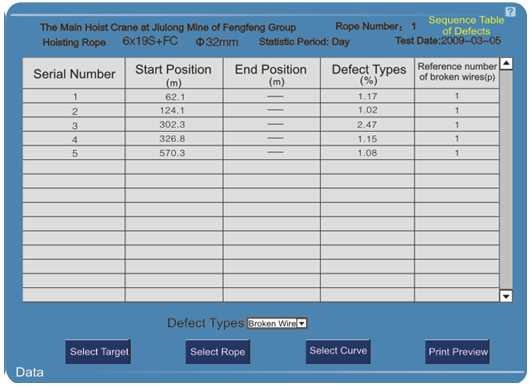

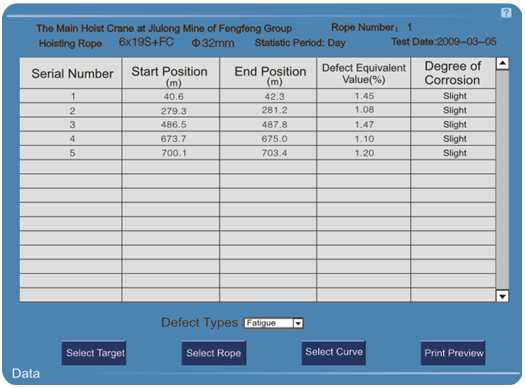

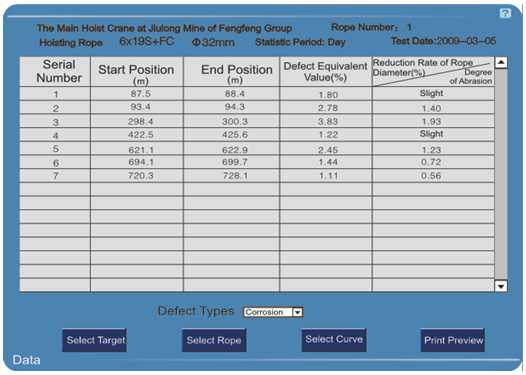

(3)Sequence Table of Defects

(3)Sequence Table of Defects

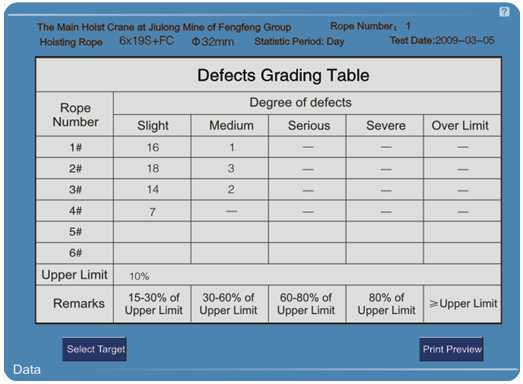

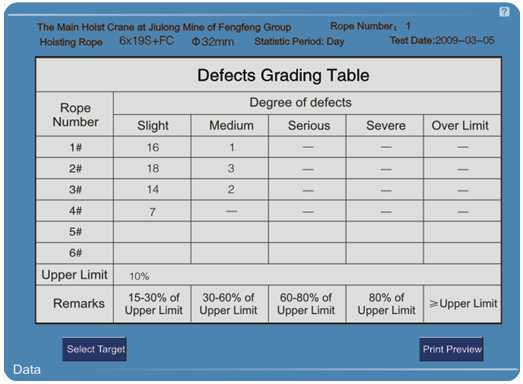

(4) Defects Grading Table

(5)Statistic Table Broken wires (within the one length of lay)

(5)Statistic Table Broken wires (within the one length of lay)